ABL

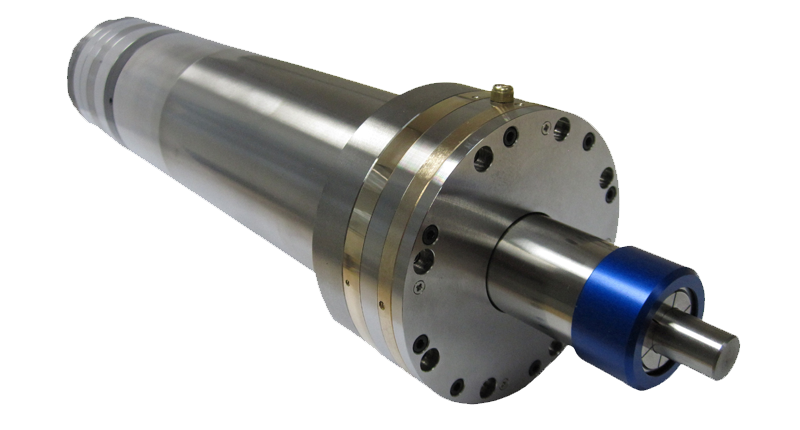

LGS10ASpindles

Specifically designed to meet the demands of the optical machining industry, the LGS10A offers exceptional rotational accuracy suited to any high precision machining or finishing operations.

The LGS10A, optimised for use at 12,000 rpm without the aid of coolant, has proved to be very popular in precision lathe manufacture of contact and intraocular (IOL) lenses. The spindle can be liquid cooled to further control thermal growth. The LGS10A provides high stiffness and very low synchronous and asynchronous error motion vital to achieving high precision surface finishes (<50 nanometres).

High load capacity bearings and exceptional tilt stiffness together with a wide variety of collet sizes makes this spindle ideal for micro-machining operations.

Offered as standard:

- Asynchronous 4 pole motor

- Automatic tool change (pneumatic actuation)

- Adjustable collet grip

- Choice of collet sizes ½”, 3/8” (other sizes available on request)

- Rear mount service ports

| Speed Range | 0 - 12,000 rpm |

| Motor Power | 550 W @ 12,000 rpm |

| Air Pressure | 5.5 BARG |

| Coolant | Water |

| Coolant Flow Rate - Water | 0.5 - 1.0 L/min |

| Coolant Inlet Temperature | 15 - 19 °C |

| Collet Size | Ø3/8" or Ø1/2" |

| Radial load (Static) | 150 N |

| Axial load (Static) | 450 N |

| Radial stiffness (Static) | 30 N/µm |

| Axial stiffness (Static) | 40 N/µm |

| Dynamic runout | < 1 µm |

| Mass | 8.8 kg |

Product Request

Please fill out this form if you would like more information about the LGS10A High-precision lens grinding Spindle.

LGS10A High-precision lens grinding Spindle

Air bearings limited © 2026 | Terms and conditions | Privacy and cookie policy